Leanne Wiseman, Griffith University and John Gertsakis, University of Technology Sydney

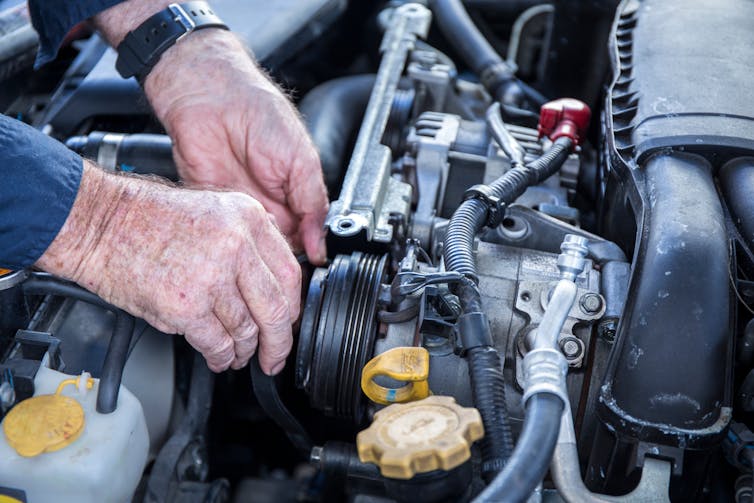

When you buy a product, you expect to be able to repair it. The problem is, many modern products are designed so that you can’t fix them. Vital parts are inaccessible. Or you have to go through the manufacturer, which may well just give you a new one. The end result: millions of expensive products, from cars to phones to appliances, end up in the rubbish tip. At the most extreme, manufacturers actively prevent you from repairing their products at the local mechanics.

You can see why some manufacturers prefer the world to work like this. If you can’t repair your washing machine, you have to buy a new one. But it’s a hidden cost to all of us – and a huge source of avoidable waste.

That’s why many countries and jurisdictions are introducing laws enshrining your right to repair products. Last month, the EU passed a ‘right to repair’ policy. In the United States, 26 states have proposed laws.

But Australia is dragging its heels.

So what’s the hold-up?

In July 2021, Australia passed its first right to repair laws, a mandated data-sharing scheme to make it possible for independent mechanics to get access to diagnostic information. This was a good start, but limited to one sector.

The Productivity Commission assessed the case for a broader right to repair almost two years ago and released its final report in late 2021.

Here, it pointed to the opportunity to give independent repairers greater access to repair supplies, and increase competition for repair services, without compromising public safety or discouraging innovation.

Shutterstock

In October last year, the new environment minister Tanya Plibersek and state environment ministers put out a joint commitment, calling for Australia to recognise the scale and urgency of environmental challenges and design out waste and pollution, keep materials in use and foster markets to achieve a circular economy by 2030.

A circular economy would mean effectively ending waste. Instead, waste streams are turned back into useful products. Many other countries are working to cut waste to a minimum.

The design of products is also a vital way to reduce waste going to landfill or, worse, the oceans. Redesigning products to make them repairable will prolong their useful life, value and functionality.

Labor has made positive sounds. But we are yet to see the promised action.

What are other countries doing?

Plenty.

America’s proposed right to repair laws vary by state in terms of what industries they cover. They range from the first ever right to repair agricultural equipment in Colorado through to all-encompassing consumer-focused laws.

Less than a month ago, the European Union passed a right to repair policy aimed at making it easier to access repairs for appliances and electrical goods. EU justice commissioner Didier Reynders estimated the laws would save consumers A$288 billion over the next 15 years. But consumer advocates say the laws don’t go far enough.

Canada is looking to reform its copyright act to introduce a consumer right to repair electronics, home appliances and farming equipment.

India, too, is exploring right to repair laws.

Why have these laws taken so long?

The main reason? Is it just government inaction or opposition by industry?

There is a long and predictable list of opponents to right to repair laws.

By and large, opposition comes from the manufacturers who see these laws as a hit to their bottom line.

Companies often deny there are any obstacles to repairing their products. Or they cite concerns over intellectual property, safety, security or environmental grounds.

But underlying all these arguments is a simpler reason: companies would make less money if consumers repaired rather than bought a new product, and less money again if they lose their hold on who can repair specific products.

Shutterstock

At present, companies win and consumers lose. When companies can direct you to only use an authorised repair outlet, there’s no risk of competition driving down the cost of repairs.

Manufacturers often respond with industry-led, voluntary initiatives such as the recent agreement between tractor giant John Deere and lobby group American Farm Bureau.

The problem is, voluntary agreements often don’t work and regulation is needed for the manufacturers to act on their promises.

As Australia grapples with its thorny plastic waste crisis, it’s a timely reminder of the need to go faster. Environment minister Tanya Plibersek used the collapse of the soft-plastics recycling Redcycle to call on industry to do more on recycling – or see new recycling regulations introduced.

What would right to repair laws mean for Australia?

If we gain the right to repair, we could:

- expect new products to be able to be repaired

- expect to be able to repair products anywhere – not just at manufacturer centres.

This would save us all money, and divert significant volumes of waste from landfill.

If we return to the old ways of repairing rather than throwing out products, we would also trigger a rebirth of repair-based businesses, employment growth and up-skilling.

But these benefits will only arrive if the government ensures any such laws are binding. ![]()

Leanne Wiseman, Professor of Law, Griffith University, Griffith University and John Gertsakis, Adjunct Professor (Industry), University of Technology Sydney

This article is republished from The Conversation under a Creative Commons license. Read the original article.

Have you been stopped from repairing something you own? Should companies have the right to lock products in this way? Let us know what you think in the comments section below.

Also read: Never keep these things on a kitchen bench

I still repair many things and when I don’t, it’s a choice. Sometimes I have to make parts or source parts from suppliers other than the original manufacturer, but I have yet to find something I can’t fix. Whether I want to can sometimes be a tough one. Depending on how much it will cost to repair and how long it will take me to repair it, sometimes I decide it is uneconomical to repair some items and then scrap them, removing parts I may reuse later.

Start with banning unique proprietary screws in domestic equipment which prevents home repair of even simple issues like faulty switches so the whole appliance has to be dumped. Then look at the repair exclusions resulting in a new switch for a $600 washing machine costing $400 but only $250 from a competant unauthorised repairer.

It is virtually impossible to obtain workshop manuals from the Australian distributors for popular machines such as Honda, Briggs and Stratton and Stihl but go online to the US distributors and it’s available. So why not in Australia? Vested interests in the politicians pockets yet again?

RESMED are a DISGRACEFUL MANUFACTURER!!

They “build in” a life cycle of 5 years so that the machine fails within the 5 years – SO YOU HAVE TO BUY ANOTHER $3,000 CPAP MACHINE!!

Equipment, appliances and all products – SHOULD BE “FIT FOR PURPOSE!!”

You should NOT have to buy a new CPAP machine every 5 years at $3,000 each BECAUSE the manufacturer says you should – and builds in a failure device timer so that it fails.

The Australian Consumer Law states that “products should be fit for purpose!” You should NOT have to buy a new washing machine, refrigerator or pool pump EVERY FIVE YEARS – so WHY should you have to buy a new CPAP machine?

RESMED are a disgusting company, based in Melbourne, who manufacture overseas, but design their products to fail! IN FIVE YEARS!! The repair centres tell you that! AND the machine tells you that! So now – the other manufacturers have done the same! TOTALLY ILLEGAL!!

I have a RESMED AirSense10 Elite, and have had it since February 2015 (8 years), and it is still working within specs. It does tell me every morning that my air pump has exceeded its operational life, but this is only a warning that the usage has exceeded the nominal life of the pump, and that it MAY fail at any time.

I have my Data dumped every 12 months, and have the Machine’s Operation checked.

I will probably update my machine in October, after the new model come out, which will make the machine 8 and a half years old.

At this point in time some of the spare parts for my machine are no longer manufactured, EG: the Humidifier Tank, and is one of the main reasons for updating.